|

Size: 676

Comment:

|

Size: 2063

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 1: | Line 1: |

| The printed circuit version is in progress using [[http://fritzing.org/|Fritzing]], and an order has been placed to [[http://fab.fritzing.org/|Fritzing Fab]] for a prototype to QA. I'll post pictures once it arrives in a couple weeks, but here are some tidbits to tantalize: * [[attachment:SpiffChorder.fzz|Fritzing file]] * [[attachment:SpiffChorderSchematic.pdf|Fritzing's schematic view (printed to PDF at 450x315mm no margins)]] * [[attachment:SpiffChorderEtchable.pdf|etchable PDF export (combined with ''pdfunite'' from ''popler-utils'')]] * [[attachment:SpiffChorderGerber.zip|compressed ZIP archive of Gerber files]] |

= Printed Circuit Board Layout = I used [[http://fritzing.org/|Fritzing]] to lay out a two-layer !SpiffChorder development board and submitted an order for the prototype to [[http://fab.fritzing.org/|Fritzing Fab]]. The fabrication cost for one unit, including international shipping to the USA, was roughly US$40. I'll post pictures once it arrives in a couple weeks and I have a chance to run tests, but here are some preliminary details: * [[attachment:SpiffChorder.fzz|a Fritzing FZZ file containing the PCB layout]] * [[attachment:SpiffChorderSchematic.pdf|Fritzing's schematic view (printed to PDF at 450x315mm with no margins)]] * [[attachment:SpiffChorderEtchable.pdf|an etchable PDF export from Fritzing (combined using pdfunite from poppler-utils)]] * [[attachment:SpiffChorderGerber.zip|a ZIP archive of the Gerber export files for the prototype (sent to me by Fritzing Fab)]] = Bill of Materials = So far I'm using the same BoM from [[ManMachine/KeyerPerfboard|the perfboard design]], but I'll probably switch up CON1 with Digikey part 609-2845-ND (vertical rather than right-angle) so as not to block the lower-left mounting hole. = Paper Placement Test = Here's a paper test using a 1:1 scale printout of the silkscreen and solder mask together: [[attachment:SpiffChorderPaperTest.jpg|{{attachment:SpiffChorderPaperTestThumb.jpg|attachment:SpiffChorderPaperTest.jpg}}]] = Connector Detail = The 0.1" pitch right-angle screw terminal blocks I used are just slightly longer than 0.4" each. So as to be able to fit the four for CON3-4 directly adjacent to one another, I lightly sanded the facing sides until they fit snugly but evenly in a piece of perfboard. In an effort to make it easier to solder these evenly on the board, I attached their sides together with a tiny dab of quick-setting adhesive gel (being careful not to get it into the terminals themselves): {{attachment:SpiffChorderScrewTerminalSanding.jpg}} {{attachment:SpiffChorderScrewTerminalsGlued.jpg}} |

| Line 7: | Line 23: |

| [[../|back to The Man-Machine...]] | [[ManMachine|back to The Man-Machine...]] |

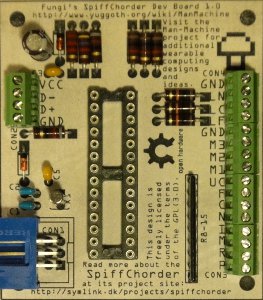

Printed Circuit Board Layout

I used Fritzing to lay out a two-layer SpiffChorder development board and submitted an order for the prototype to Fritzing Fab. The fabrication cost for one unit, including international shipping to the USA, was roughly US$40. I'll post pictures once it arrives in a couple weeks and I have a chance to run tests, but here are some preliminary details:

Fritzing's schematic view (printed to PDF at 450x315mm with no margins)

an etchable PDF export from Fritzing (combined using pdfunite from poppler-utils)

a ZIP archive of the Gerber export files for the prototype (sent to me by Fritzing Fab)

Bill of Materials

So far I'm using the same BoM from the perfboard design, but I'll probably switch up CON1 with Digikey part 609-2845-ND (vertical rather than right-angle) so as not to block the lower-left mounting hole.

Paper Placement Test

Here's a paper test using a 1:1 scale printout of the silkscreen and solder mask together:

Connector Detail

The 0.1" pitch right-angle screw terminal blocks I used are just slightly longer than 0.4" each. So as to be able to fit the four for CON3-4 directly adjacent to one another, I lightly sanded the facing sides until they fit snugly but evenly in a piece of perfboard. In an effort to make it easier to solder these evenly on the board, I attached their sides together with a tiny dab of quick-setting adhesive gel (being careful not to get it into the terminals themselves):

To the extent possible under law, the creator of this work has waived all copyright and related or neighboring rights to it.

To the extent possible under law, the creator of this work has waived all copyright and related or neighboring rights to it.